Systems can be built to include endothermic or exothermic protective atmospheres, discharge chute, water or oil quench tank with take out conveyor.

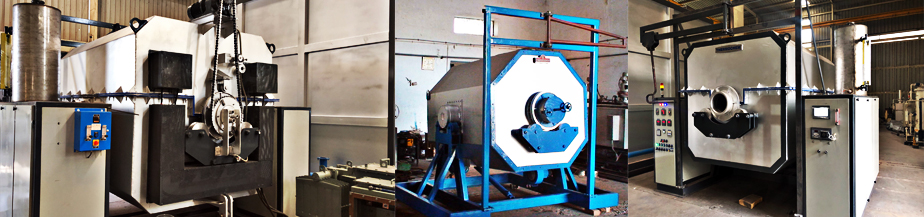

A wide range of electrically heated or gas-fired rotary retort furnaces suitable for processing small parts such as piston pins, ball bearing balls, small bearing races, universal joints, bolts, nuts, sheet metal screws, etc..

Features

Applications

Options

Features

- Heavy gauge cast alloy retort with integral spiral

- Roller guide support each end of retort

- Variable speed retort transmission with Gear Motor Unit

- Front charge cone is atmosphere sealed.

- Fabricated continuously welded and reinforced steel retort

- Endothermic gas atmosphere system standard

Applications

- Carbonitriding

- Carburizing

- Hardening

- Normalizing

- Tempering

Options

- Automation for tilting of furnace with Hydraulic System.

- Carbon control with oxygen probe

- Gas flowmeters for dissociated ammonia or exothermic atmospheres

- Nitrogen-methanol atmosphere system

- Temperature control and recorder options

- Quench tank

- Quench tank exit conveyor