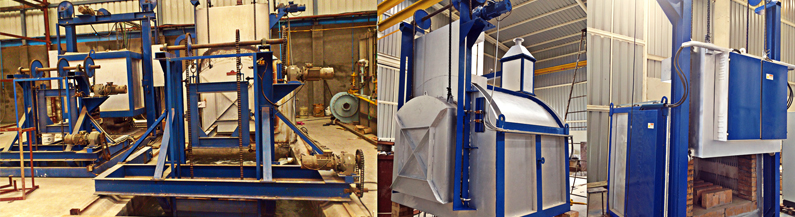

The rapid, uniform heating of the Box / Chamber Type Furnace has been proven in hundreds of installations. It is very productive as the cycle time is minimized by the rapid heating capability and a very heavy and dense load can be uniformly treated. These furnaces include unique insulation and heating system composites to minimize outer surface temperature while maintaining uniform heat distribution within the chamber.

Features

Benefits

Applications

Features

- Temperature Range up to 1250 Deg. C. with our without atmosphere.

- Available In Electric/Oil/Gas Heating System

- Light weight ceramic fiber board insulation with embedded heating elements in Electrical Hearting System or dense HFK backed by insulation bricks on side and top walls in Oil/Gas Heating System.

- Oil / Gas heating system consists of combustion system of high velocity gas/air burners.

- Electric Heating System consists of each movable and replaceable heating elements.

- Modular construction for ease of installation.

- Vertical rise and fall type door with electro-mechanical drive system.

- Grooved hearth construction is also available, which is suitable for loading/unloading and quenching of material with the help of hydraulically or electro-mechanically operated elevator.

Benefits

- Excellent efficiency in all types of work

- Accurate temperature control

- Excellent uniformity throughout work chamber

- Exceptional resistance to thermal shock

- Easy to service

- Low maintenance

Applications

- Aging

- Annealing

- Hardening

- Normalizing

- Pre Heating

- Solution Treating

- Stress Relieving

- Tempering

- Shell Backing