Worldwide Supplier of Log Homogenizing Furnace Manufacturers in India

Thermochem Furnaces Pvt. Ltd.is the worldwide supplier of log homogenizing furnace manufacturers in India. The custom-engineered furnaces we supply are most fit for all types of process applications. The latest technology and the best practices in the industry enable us to provide unique furnaces suitable for various industrial purposes.

Our log homogenizing furnace manufactures in Europe produce furnaces that are based on modular construction, manufactured with steel frames and with quality insulations. According to the expected final product, the thermal cycle is adjusted. The furnaces of long homogenizing furnace manufacturers in Saudi Arabia are designed to work as automatic solutions. These solutions have the automatic ability to maintain the set point temperature for the billets inside them.

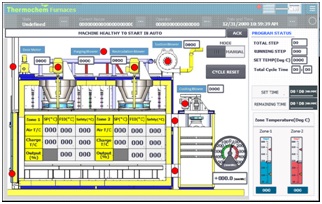

The log homogenizing furnace manufacturers in USA is a leading producer of furnaces charging machines. Combined with charging machines, furnaces work automatically. Control is maintained by PLC systems with HMI interfaces that permit control of the procedure through menus for each size and composite in addition to extra custom-developed menus. Along these lines, each batch can be treated as per the exceptional prerequisites of individual clients or for explicit results.

The log homogenizing furnace manufactures in UAE enables cooling inside the furnace by permitting the initial cooling down of the billets following the metallurgical prerequisites for ideal attributes of the homogenized results. Furnaces of log homogenizing manufactures in Australiacan use gas, light fuel oil or electrical energy for heating. Irrespective of the industry, we can provide you with suitable furnaces that are apt for hard environments.

25MT per Batch Chamber Type Aluminium Heat treatment furnace for Foil/Coils

15MT per Batch Chamber Type Aluminium Heat treatment furnace for Foil/Coils

Batch type Chamber Furnaces for Heat Treatment of Aluminium Foils / Coils

Degreasing , Intermediate & final annealing of ultra-thin to heavy-gauge foil, wound on large or narrow coils. The annealing atmosphere can be selected (air or nitrogen) to prevent brown discoloration due to oil stains, sticking or oxidation of foil layers.

Thermochem annealing furnaces are flexible to support both slow heating of ultra-thin, sensitive foil and maximum heating / cooling rates for heavy-gauge material . Further it allows the rolling lubricant to evaporate without trace so that sticking is prevented and the necessary surface cleanliness is guaranteed through Purge and Vacuum system. Anneals in process atmosphere provide the advantage that the necessary surface cleanliness is achieved in the shortest time because the atmosphere promotes evaporation of the rolling lubricant, reducing the risk of the oil cracking on the foil surface.

These furnaces can be complied with automotive and aerospace standards mainly AMS 2750E (SAE Aerospace) in the aircraft industry and CQI-9 (AIAG) for the automotive industry.

Benefits :-- Temperature Uniformity :- Δt less than ±3°C at the end of the soaking time

- Metal Heating & Air Heating control mode for faster heating & achieve higher furnace Efficiency.

- Inert gas provision to prevent oxidation of charge materials

- By pass /Separate Cooling arrangement for faster cooling after completion of heat treatment cycles

- Furnace have the provision of connecting to you existing Industry 4.0 networks

- Providing higher value to the customer compared to other suppliers

- Maximum Demand Load management for Multi Furnaces installed without affecting the temp control system of each furnaces

Intermidiate and Final Annealing of Aluminium Foils/Coils